-

- High Energy Consumption

-

Large-scale municipal buildings such as government office buildings, exhibition halls, and libraries have open spaces, diverse functions, and frequent pedestrian flows. The air conditioning systems need to operate for a long time and cover a large area. Traditional air conditioning equipment has relatively low energy efficiency, resulting in persistently high energy consumption. This imposes a heavy burden on municipal operation costs and runs counter to the current policy orientation of energy conservation and emission reduction.

-

- Difficulty in Ensuring Comfort

-

Different areas have various functions, and there are significant variations in personnel density, activity patterns, and heat and moisture loads. For example, in the conference area, people gather and generate a large amount of heat. Exhibition halls have special requirements for temperature, humidity, and air cleanliness due to the protection of exhibits. Traditional single-mode air conditioners are difficult to adjust precisely, and problems such as local overheating or overcooling, dry and stuffy air are likely to occur, affecting the comfort and work efficiency of users.

-

- Complex System and High Difficulty in Operation and Maintenance

-

The air conditioning systems of municipal buildings cover a variety of equipment, such as chillers, cooling towers, air handling units, fan coil units, etc. All components work in coordination. Once a certain link fails, troubleshooting and repair are time-consuming and labor-intensive. Moreover, the operating parameters of the system need to be dynamically adjusted according to seasons and time periods, which requires extremely high technical levels and experience of operation and maintenance personnel. A slight mistake will affect the overall performance.

-

Solution Overview

Adopt High-efficiency and Energy-saving Air Conditioning Technologies

Introduce variable frequency technology to enable key equipment such as air conditioning main units, water pumps, and fans to dynamically adjust their rotation speeds according to the actual load, precisely matching the cooling and heating requirements of the building and avoiding energy waste. Select high-efficiency heat recovery devices to recover the waste heat of exhaust air for preheating fresh air or heating domestic hot water, improving energy utilization efficiency. Combined with an intelligent control system, it can monitor indoor and outdoor environmental parameters in real time, optimize the operation strategy of the air conditioner, and achieve a significant improvement in energy conservation.

Personalized Zoned Air Conditioning Design

According to the functional zones of municipal buildings, such as office areas, public service areas, and equipment machine rooms, design independent air conditioning subsystems. For the characteristics of heat and moisture loads in different areas, configure appropriate terminal equipment and control methods to ensure that the comfort level of each area meets the standard.

Build an Intelligent Operation and Maintenance Management Platform

Utilize Internet of Things, big data, and cloud computing technologies to connect the sensors of all equipment in the air conditioning system, and collect operation data in real time and upload it to the cloud. Through data analysis algorithms, the platform can provide early warnings of potential equipment failures, automatically generate operation and maintenance plans, and guide technicians to carry out precise repairs. At the same time, the remote monitoring and control functions allow operation and maintenance personnel to adjust system parameters anytime and anywhere, reducing the frequency of on-site inspections and improving operation and maintenance efficiency.

-

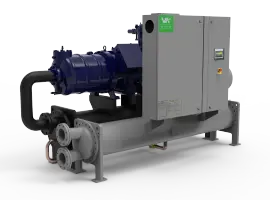

In Terms of High-efficiency and Energy-saving Technologies

The VWCF Veck air-bearing variable frequency centrifugal chiller independently developed by Veck is a centrifugal chiller adopting the internationally leading dynamic pressure gas bearing structure. The product applies a number of core technologies such as dynamic pressure gas bearings, high-efficiency permanent magnet synchronous motors, two-stage compression, and secondary subcooling. It has many characteristics including oil-free and high-efficiency operation, stability and reliability, cost savings, low noise, and environmental friendliness, and is at an internationally advanced level. At the same time, it is equipped with a reliable industrial-grade microcomputer control system, group control technology, and building communication interfaces, ensuring excellent operability and rich expandability of the unit. The product has remarkable energy-saving effects; its core technologies are independently controllable, and it can be custom-developed according to customers' needs to be adapted to different working conditions; the cost throughout the whole life cycle is low, which reduces long-term operating expenses and shortens the investment payback period.

-

In Terms of Personalized Zoned Air Conditioning Design

The design team of the company has conducted in-depth research on the functional layout of municipal buildings and tailored air conditioning solutions for each area, which has significantly improved the comfort level, effectively enhancing the satisfaction and work efficiency of office workers. Precise environmental control is conducive to extending the lifespan of exhibits and protecting public facilities. Diverse terminal selections and professional designs can address complex architectural space and functional requirements, making the project highly adaptable.

-

In Terms of the Intelligent Operation and Maintenance Management Platform

For Veck's CPS intelligent platform, high-precision sensors are deployed at key parts of the air conditioning equipment on the hardware side. On the software side, relying on the big data analysis engine, an equipment failure prediction model is established. Through machine learning algorithms, the operation data is compared with historical failure data in real time. Once an abnormal trend is detected, early warning information will be pushed in advance to the mobile APP and computer terminal of operation and maintenance personnel. At the same time, the system has a built-in remote control module. Authorized operation and maintenance personnel can remotely start and stop the equipment, adjust the operation parameters, and also view historical operation reports and generate energy consumption analysis curves, providing data support for optimized management.

Map Guide

Map Guide

Business Cooperation

Business Cooperation

Fault Repair

Fault Repair

Complaints & Suggestions

Complaints & Suggestions