-

- High Requirements for Environmental Temperature Control

-

In the new energy industry, processes such as battery production, energy storage systems, and the manufacturing of certain electronic equipment are highly sensitive to ambient temperature. Excessively high or low temperatures can adversely affect battery performance, lifespan, and the stability of electronic devices.

-

- Difficulty in Humidity Control

-

An appropriate humidity level is crucial for the production and storage of new energy products. Excessively high humidity may lead to problems such as short circuits and corrosion of electronic components. On the other hand, too low humidity is likely to generate static electricity, which can damage delicate components. However, new energy production workshops usually have a large space, making it difficult to achieve precise humidity control.

-

- High Requirements for Cleanliness

-

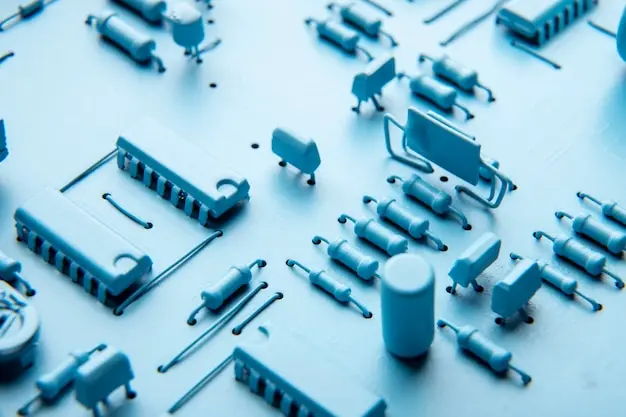

The production environment of new energy needs to maintain a high level of cleanliness. Pollutants such as dust and particles may affect product performance. Especially in the processes of chip manufacturing and battery assembly, even tiny impurities may cause product failures. Therefore, there are high requirements for air purification.

-

- High energy consumption

-

Production equipment in the new energy industry typically has high power consumption and generates significant heat during operation, requiring continuous cooling to maintain a suitable environment. Traditional air conditioning systems are energy-intensive, increasing operational costs and conflicting with the new energy industry's pursuit of energy efficiency and environmental protection.

Solution Overview

Integrated Technology, Precision Control, and Efficiency Enhancement

With its professional technology and rich experience in the air conditioning field, Veck provides a comprehensive, efficient, and customized air conditioning solution tailored to the special needs of the new energy industry. We integrate advanced refrigeration technology, intelligent control systems, and high-efficiency air purification equipment. Our aim is to create a comfortable environment for new energy enterprises where the temperature, humidity, and cleanliness all meet the production requirements. At the same time, it can effectively reduce energy consumption, improve production efficiency, and enhance product quality.

-

Precise Temperature Control

Veck adopts an advanced intelligent temperature control system. It monitors the environmental temperature in real time through high-precision sensors and automatically adjusts the cooling capacity and air supply volume according to the preset parameters. The refrigeration system uses efficient compressors and an optimized refrigeration cycle design, which can quickly respond to temperature changes. This ensures that the temperature in the workshop is always maintained within the set range, effectively meeting the strict temperature requirements of battery production, electronic device manufacturing and other processes. It reduces product quality problems caused by temperature fluctuations and improves product consistency and the yield rate.

-

Accurate Humidity Control

It is equipped with Veck's professional and efficient rotary dehumidifier, which has a high dehumidification efficiency. It can precisely control the humidity of the room, effectively avoiding problems such as short circuits and corrosion of electronic components caused by excessive humidity, as well as the static electricity phenomenon caused by low humidity. It comprehensively safeguards the safety of production equipment and products.

-

Efficient Air Purification

A multi - stage air filtration system is employed, including primary, medium - efficiency, and high - efficiency filters. This system can effectively filter out pollutants such as dust, particles, and microorganisms in the air. It can meet the strict requirements for air cleanliness in the new energy industry, effectively reducing the risk of product failures caused by pollutants and enhancing product quality and reliability.

-

Energy Saving and Consumption Reduction

Veck adopts high - efficiency energy - saving technologies to reduce energy consumption. Meanwhile, the optimized heat recovery system can recycle the waste heat generated during the refrigeration process, further improving energy utilization efficiency.

Map Guide

Map Guide

Business Cooperation

Business Cooperation

Fault Repair

Fault Repair

Complaints & Suggestions

Complaints & Suggestions