-

- Poor Adaptability to Harsh Environments

-

Industrial production sites are often filled with harsh conditions such as a large amount of dust, oil stains, corrosive gases, and high temperature and humidity. Ordinary air conditioners are difficult to operate stably for a long time in such environments. Problems such as filter screen blockage, component corrosion, and electrical failures occur frequently, resulting in high maintenance costs and frequent downtime, which seriously affects production continuity.

-

- Difficulty in Precise Temperature and Humidity Control

-

Different industrial processes have strict and diverse requirements for environmental temperature and humidity.

-

- Poor Energy-saving Effect

-

Industrial factories have a large space and equipment generate a large amount of heat, so the air conditioning system operates under high load for a long time. However, many existing air conditioning solutions have not been optimized for the characteristics of industrial loads, and there is a phenomenon of "using a big horse to pull a small cart". The cold and heat source equipment operates inefficiently during some periods, and there is a lack of effective energy recovery and intelligent control means, resulting in serious energy waste and a rise in the operating costs of enterprises.

-

- Complex system integration and maintenance

-

Industrial production processes are diverse, involving numerous functional areas with different air conditioning needs, requiring the construction of complex centralized or distributed air conditioning systems. However, the poor compatibility of different brands and models of equipment makes system integration difficult, and later maintenance involves cumbersome troubleshooting and spare parts management. Once problems occur, the long response time for repairs affects overall production progress.

Solution Overview

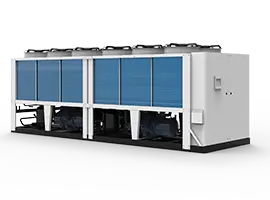

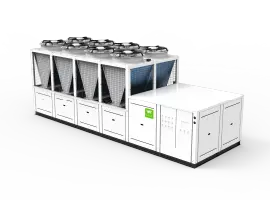

Customized Environmental Adaptability Design

To deal with harsh working conditions, Veck Company can customize the outer shell of the air conditioning unit, which has the characteristics of dust prevention, oil prevention, and corrosion resistance. A multi-stage filtration system is designed internally, combining primary, medium, and high-efficiency filters to effectively block tiny particles and extend the service life of core components. At the same time, the heat dissipation structure is optimized, and high-efficiency heat exchangers and high-temperature-resistant condensing fans are used to ensure stable cooling and heating in high-temperature environments.

High-precision Intelligent Control System

High-precision temperature and humidity sensors are developed to collect environmental data in real time and feed it back to the intelligent control system. This system uses advanced PID algorithms to precisely adjust the operating frequencies of equipment such as compressors, fans, humidifiers, and dehumidifiers, achieving precise control of temperature and humidity, and can flexibly switch operating modes according to preset programs.

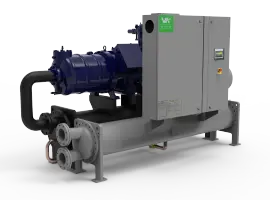

Integration of High-efficiency Energy-saving Technologies

According to the changing laws of industrial loads, a cold and heat source unit driven by a frequency converter is designed to achieve the output of cooling capacity and heating capacity on demand. A heat recovery device is configured to recover the heat in the exhaust air of the air conditioner for preheating fresh air or reheating the air, greatly improving energy utilization. An intelligent energy management platform is built to monitor energy consumption data in real time. Through big data analysis and machine learning algorithms, the operating strategy of the air conditioning system is automatically optimized to reduce comprehensive energy consumption.

One-stop System Integration

Veck independently develops standardized air conditioning system integration modules to ensure seamless connection of different components.

-

Customized Design

For projects exposed to acid and alkali corrosion, 304 stainless steel plates are used for the outer shell. This effectively protects against corrosion from acids, alkalis, and salt fog. In the filtration system, different filters can be combined based on the specific requirements of each project to comprehensively address air cleanliness issues.

-

High-precision Intelligent Control

The control system has multiple preset modes tailored for various industrial processes. With a single click, users can precisely adapt to the corresponding environmental requirements. Precise environmental control can significantly reduce the defective product rate during industrial production. As a result, it substantially improves product quality and boosts the economic efficiency of enterprises.

-

High-efficiency Energy-saving Technology

The CPS intelligent platform is based on the Internet of Things architecture independently developed by Veck. The collected data covers multi-dimensional information such as equipment energy consumption, environmental parameters, and operation time. Through big data analysis in the cloud, it explores the potential for energy conservation. It sends an energy conservation optimization report to users every week and can remotely execute adjustments to energy conservation strategies.

-

Professional Services

In the early stage of the project, a team of experienced engineers is dispatched to conduct in-depth on-site investigations. Based on factors such as the production process, factory layout, and pedestrian flow, professional simulation software is used to calculate the load of the air conditioning system and design the solution. This ensures accurate equipment selection and effectively reduces the failures and problems that may occur during the later operation of the air conditioning system.

Map Guide

Map Guide

Business Cooperation

Business Cooperation

Fault Repair

Fault Repair

Complaints & Suggestions

Complaints & Suggestions