-

- High Requirements for Temperature and Humidity Control

-

The control of temperature and humidity during the food processing process is extremely strict. Any slight fluctuation may have an adverse impact on the product quality.

-

- High Requirements for Safety and Hygiene

-

Food processing workshops need to prevent pollution and maintain strict hygiene standards, which poses higher challenges to the design and operation of the air conditioning system. If the air conditioning system cannot effectively filter pollutants such as dust and bacteria in the air, it may contaminate the food and lead to food safety problems.

-

- High Energy Consumption

-

While meeting production requirements, traditional air conditioning systems often have high energy consumption, increasing the operating costs of enterprises.

-

- High requirements for equipment stability and reliability

-

Food processing enterprises have extremely high requirements for the stability and reliability of equipment. Equipment failure may lead to production interruptions, affecting product quality and corporate reputation. In continuous food production lines, if the air conditioning equipment fails, it may not only stop production but also cause food spoilage, resulting in huge economic losses and brand trust crises.

Solution Overview

Optimizing Efficiency, Hygiene, and Sustainability

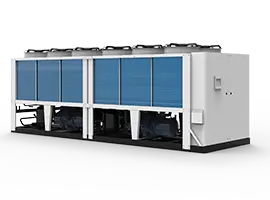

Aiming at the characteristics of the food processing industry, Veck provides a comprehensive air conditioning solution. Through efficient temperature and humidity control, strict air purification, energy conservation and consumption reduction, as well as intelligent management, this solution ensures the safety, hygiene and stability of the food processing environment, helping enterprises improve product quality and production efficiency and reduce operating costs. Veck's solution not only focuses on the performance and quality of the equipment, but also pays attention to the intelligence, energy conservation and environmental protection of the system, and is committed to providing food processing enterprises with an efficient, reliable and economical air conditioning system.

-

Precise Control Technology

Veck's air conditioning system adopts advanced sensors and intelligent control systems, which can monitor and precisely control the temperature and humidity in the workshop in real time, ensuring that the products are always in an excellent production environment.

-

High Flexibility

There is a wide variety of food production, and different products have different requirements for temperature and humidity. Veck's air conditioning system has good flexibility and can be quickly adjusted according to the needs of different products.

-

High-efficiency Filtration Technology

Veck's air conditioning system uses high-quality brand filters and combines professional design to optimize the uniformity of the cross-section, reducing the wind speed and wind resistance, which greatly extends the service life of the filters.

-

Energy Recovery Technology

The intelligent energy recovery control system independently developed by Veck can precisely match the real-time load requirements of the workshop, dynamically adjust the operating status of each component of the air conditioning system, achieve the utilization and recovery of energy, and solve the problem of "hot and cold offset".

Map Guide

Map Guide

Business Cooperation

Business Cooperation

Fault Repair

Fault Repair

Complaints & Suggestions

Complaints & Suggestions