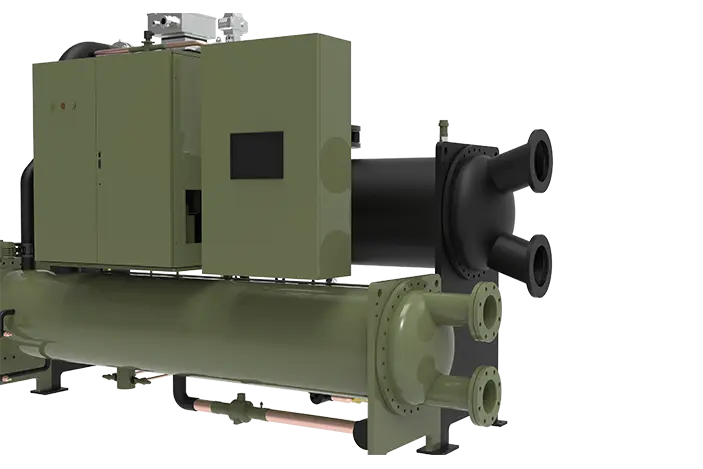

Product Overview

Product Overview

Cooling Capacity Range

Cooling Capacity Range

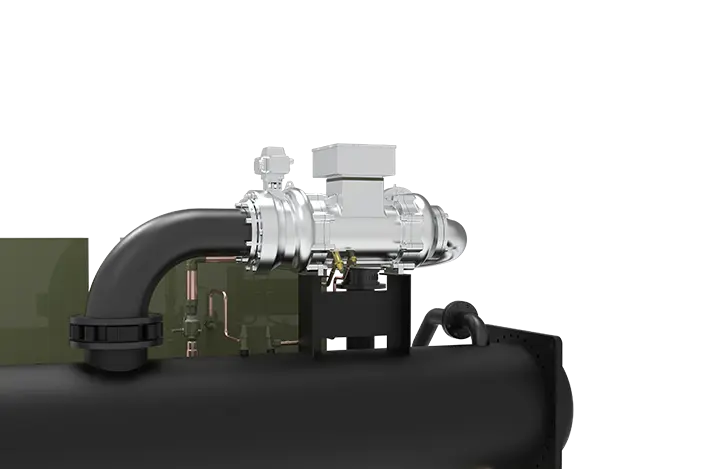

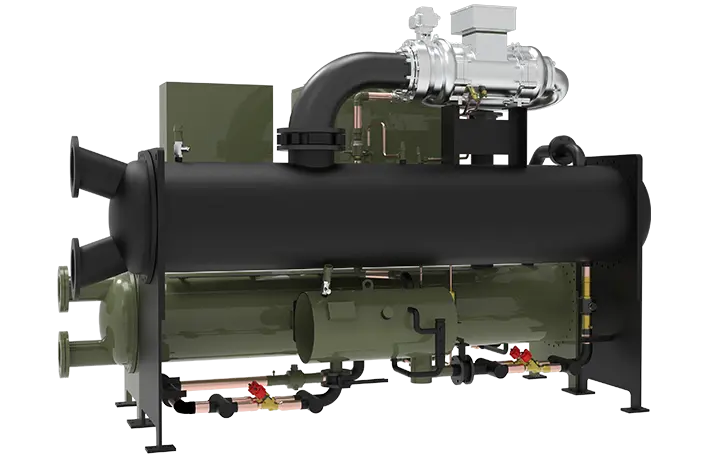

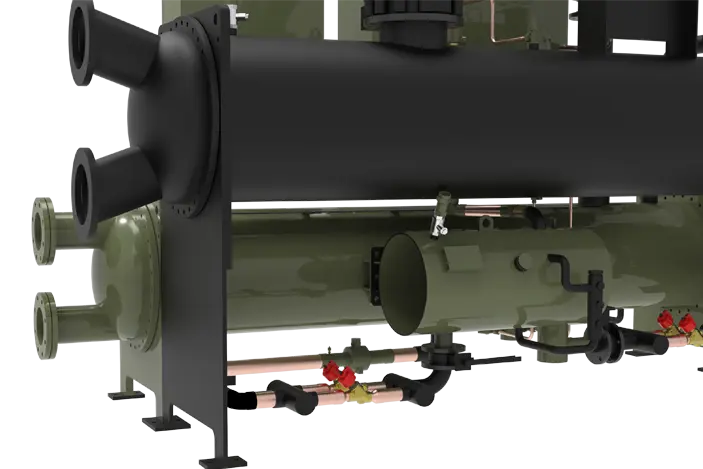

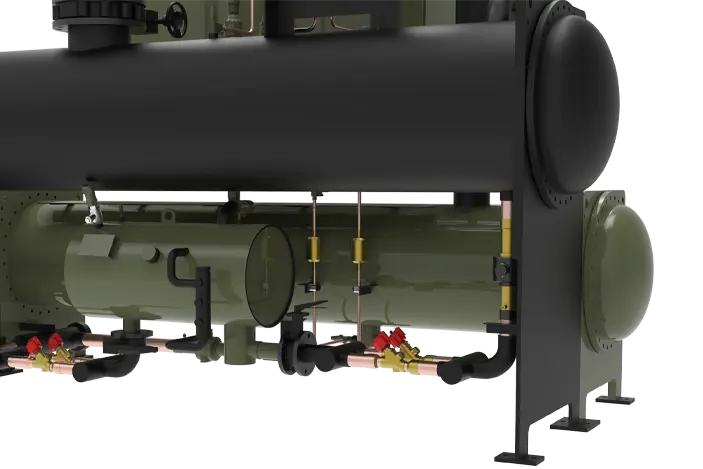

Equipped with a high-efficiency flooded heat exchanger, it incorporates patented uniform liquid distribution plates, liquid baffle design, and a new generation of double-sided enhanced high-efficiency evaporator tubes, significantly improving heat transfer performance.

The patented shell-and-tube condenser with turbulence-enhancing design doubles the subcooling degree. Additionally, the use of a counterflow subcooling chamber and high-efficiency condensing tubes ensures stable and highly efficient condensation, significantly improving overall condensing performance.

The use of a flash tank significantly increases refrigeration capacity, reduces power consumption, and optimizes the refrigeration cycle.

A well-known domestic brand is adopted, enabling precise flow control and rapid response.

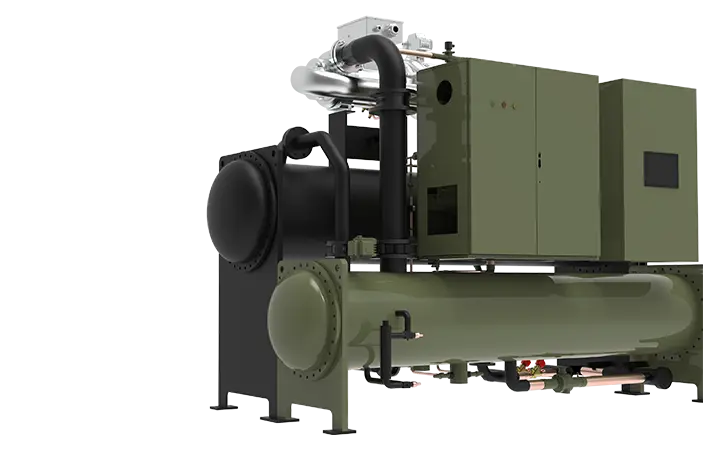

The unit features an onboard refrigerant-cooled VFD with a wide voltage range design, offering a more compact size and higher power density. It enables high carrier frequency operation without derating and comes standard with a harmonic filter to ensure stable VFD performance.

The self-programmed controller ensures fast response and stable operation, supporting multiple communication protocols such as Modbus, BACnet, SNMP, and OPC-UA for powerful and flexible control. Additionally, it incorporates energy-saving optimization, anti-surge protection, ambient temperature auto-compensation (temperature reset), and adaptive control strategies, significantly improving the unit's energy efficiency ratio (EER).

An industrial-grade high-reliability touchscreen is adopted, featuring controller network port communication with anti-interference and reliable data transmission. It enables real-time monitoring of unit status, providing a dependable safeguard for stable operation.

Map Guide

Map Guide

Business Cooperation

Business Cooperation

Fault Repair

Fault Repair

Complaints & Suggestions

Complaints & Suggestions